Improving performance of a novel laparoscope attachment

During a minimally invasive procedure, a laparoscope's lens has to be maintained

clean as the adequate vision is crucial for a safe surgical procedure.

Cipher Surgical developed a novel laparoscope attachment - OpClear®

that directs an 'on demand' jet of CO2 across the lens, removing blood,

peritoneal fluid, particulate matter and condensation/fogging.

This allows the surgeon to maintain a clear view during the whole operation, therefore

maximising time, enhancing safety and minimising the frustration of

having to stop or working with reduced vision.

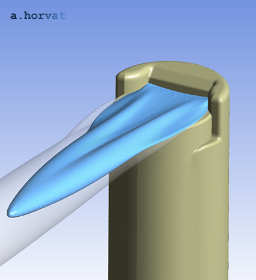

Laparoscope with the OpClear® attachment [ ... rotate the graphics with the mouse ]

Computational Fluid Dynamics (CFD) analysis was used to importantly influence the design of the attachment

exit section in order for the CO2 jet to provide adequate coverage of the laparoscope lens

and the related cleaning potential. Any flow recirculation areas inside the attachment

were minimized to develop a uniformly plane distribution of the exiting flow. The total pressure

distribution along the exiting jet was analysed in detail as it is proportional to the force

the surrounding tissue is subjected to.

CFD analysis of the OpClear® attachment: cleaning jet velocity isosurfaces

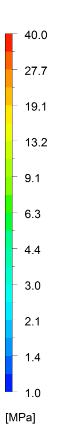

The calculated gas pressure was used as a structural load on the attachment to predict stresses and

attachment deformations using Finite Element (FE) analysis. The influence of different material

properties on the attachment's structural behaviour was also investigated.

Distribution of von Mises stress in the OpClear® laparoscope attachment [ ... rotate the graphics with the mouse ]

The conducted structural FE analysis revealed stress concentration areas where the material is

most prone to cracking. It also showed the contact areas between the laparoscope and the attachment,

and how their location changes with the attachment deformation. Locations of submillimeter-size gaps

were identified. They may lead to gas leakage, which reduces

the strength of the exit gas jet and its cleaning potential.

Dr Andrei Horvat

M.Sc. Mechanical Eng.

Ph.D. Nuclear Eng.

phone

+44 79 72 17 27 00

skype

a.horvat

e-mail

mail@caspus.co.uk

M.Sc. Mechanical Eng.

Ph.D. Nuclear Eng.

phone

+44 79 72 17 27 00

skype

a.horvat

mail@caspus.co.uk